Water shortages, testing, quality expenses, and ETPs are important issues for pharma manufacturing companies.

Pure and clean water is very essential for the pharmaceutical production process. Its an urgency for manufacturers to begin with drinking water and purify it further to standards depending on the use.

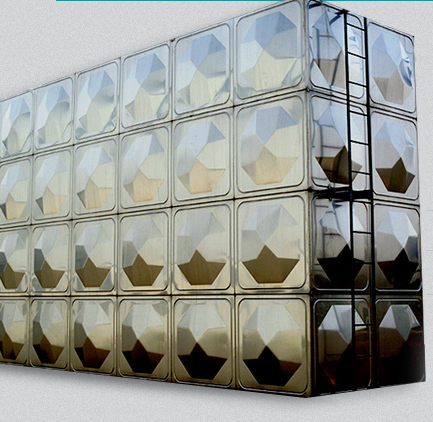

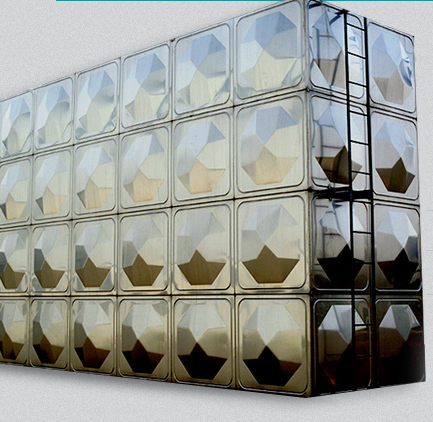

Advanced purified water purification systems are well designed and generally do not have any problems meeting clean water requirements. Not only purifying the water is important but storing it also a major point.

Water shortage in Pharma production.

Drinking water-the source for purified water for pharma-is a limited resource. The World Health Organization (WHO) predicts that by 2025, half of the world’s population will “be living in water-stressed areas.”

"Although numbers vary regarding the severity of this complex problem, the Water Resources Group predicts that, if nothing is done to improve efficiency, global water demand would be 40% more than accessible, reliable supply by 2030".

Zero liquid discharge, a concept that is new to the pharma industry, is a potential solution to the water-shortage problem that involves recycling or reusing process water. We have already written so many blogs on zero liquid discharge.

“There are many uses for water; the key is how to reuse what is being sent to the drain-maybe in the process itself, or in cooling towers or building sanitation systems.

For example, you could take water draining from the clean-in-place system and retreat it or use it for tertiary systems in the building.

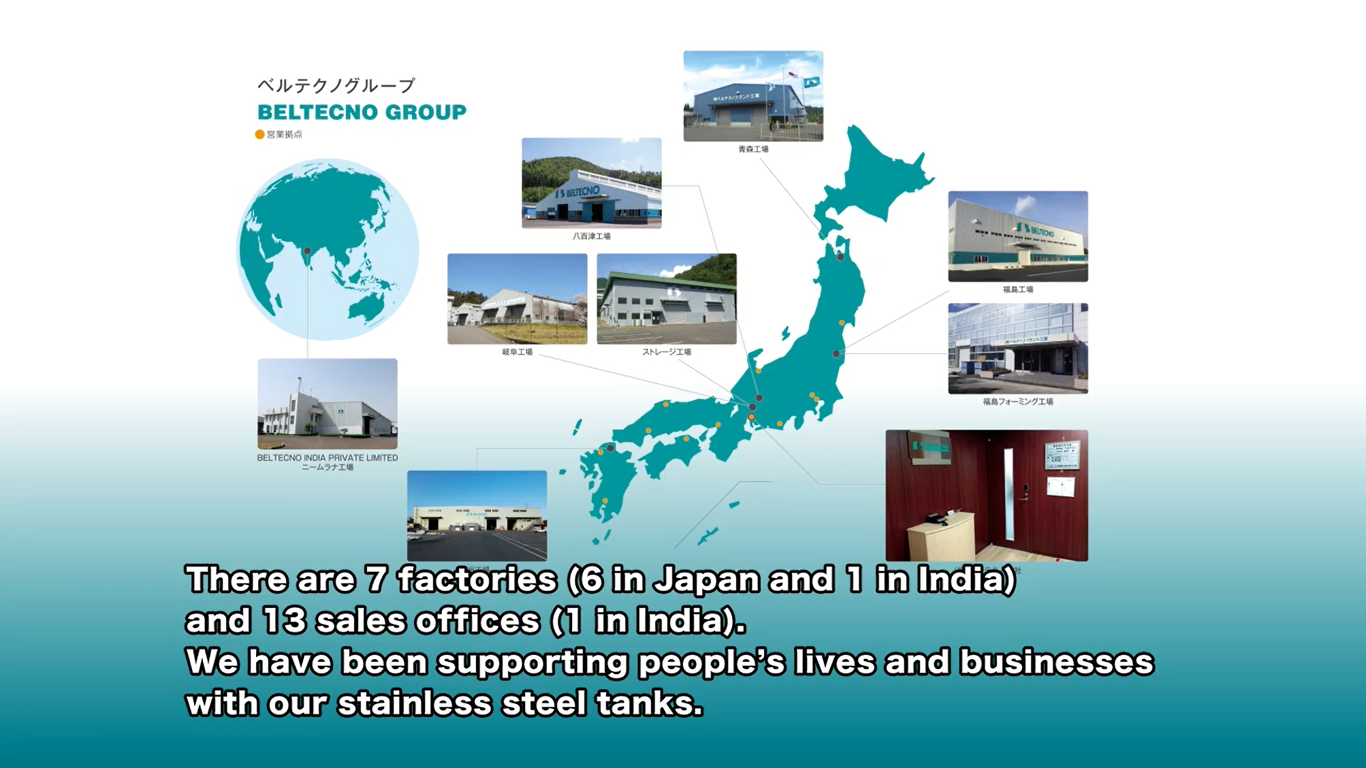

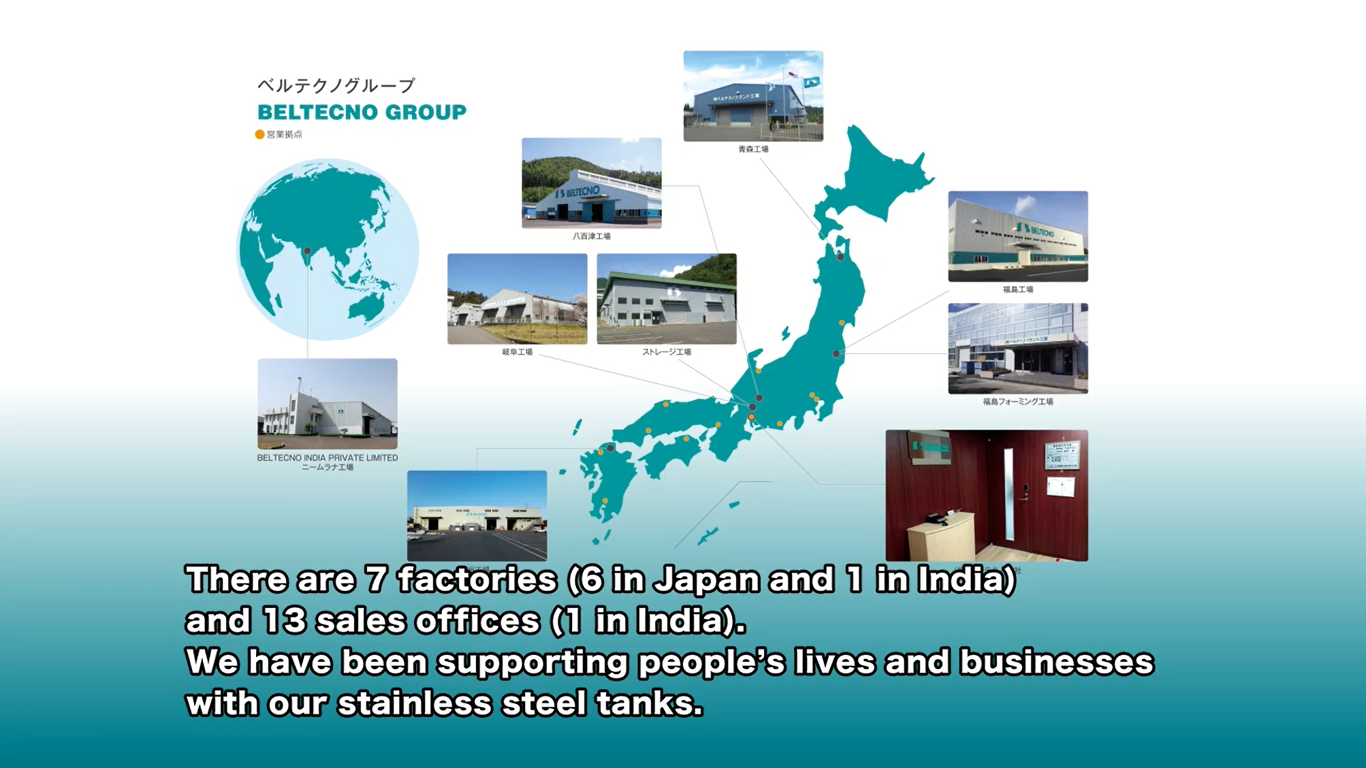

Beltecno India is one of the major suppliers of stainless steel panel tanks in India and helping pharma companies to store treated water in more hygienic way.

.jpg?width=900&name=New%20Project%20(3).jpg)

For more information regarding our stainless steel panel tanks download our product brochure by clicking the button below, drop us your requirement on sales@beltecnoindia.com or call us on any of the given numbers +91 9116009580/+91 7300084028

For more Details on Our Product click here

Check our blogs

.jpg?width=900&name=New%20Project%20(3).jpg)