For more Details on Our Product click here ![]()

*https://pubs.spe.org/en/ogf/ogf-article-detail/?art=3566

For decades, large capacity water tanks were utilized to hold huge amounts of drinking, irrigation, emergency, and also even agricultural application water. Global economies i.e. United States, UK, Japan etc. were not just one of the leading countries in the usage of the modern technology, yet these were among one of the biggest consumers and understood the value of drinking water long back. A great deal of the drinking, irrigation, and emergency situations could be found in rural areas where the population density was low, such as India.

An equivalent of 70% of the India population relied on groundwater sources for their primary supply. Most individuals who lived within these parts would recycle a considerable part of the drinking, irrigation and emergency water because of the absence of pipelines in certain regions. Nevertheless, after the pipes had been made and pipelines became widespread, then the majority of the people began using them instead of the old methods.

Concrete water tanks were made for this particular purpose (To distribute water on time in localities). About 40% of the world's fresh drinking water got stored inside concrete water tanks. These days, even the most common plastic water tanks also been utilized. However, if you plan to utilize them again, you may require an environmentally friendly method to dispose of the plastic tanks afterwards, to avoid any kind of potential environmental hazard.

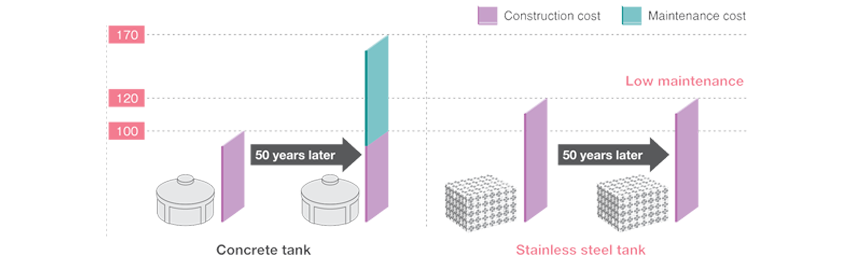

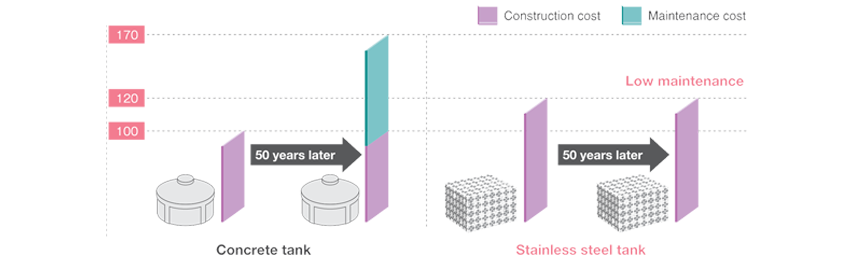

However plastic tanks are way cheaper then Concrete tanks but concrete tanks historically considered to be an inexpensive choice for water storage. But an analysis conducted in Philadelphia found that stainless steel water tanks cost is substantially less than concrete ones to build and maintain. During a 45 to 50 year lifespan, concrete water tanks there cost more than millions, almost 15,000,00 - 20,000,00 Lakh (INR) per year.

In contrast, If a stainless steel water tank will be used for around the same number of years cost a little over 25,000,00/- INR total. Installation, repairs, and removal costs will be much higher with concrete vs steel water tanks, overall, even this cost can be recovered from the scrap value of the stainless steel panel tank after use.

They're more durable Just put, concrete tank are prone to cracks. They tend to leak and are susceptible to corrosion, expansion, and contraction from varying temperature and harsh weather. This can cause the liquid inside to leak out. These damages can result in costly repairs and will effectively make the concrete tank useless after few years. Stainless steel tank are resistant to corrosion with good heat resistance and hygiene properties. ,which means they'll endure for much longer.

Stainless Steel Water Tanks are more mobile. Concrete tanks are poured into place and are meant to stay at the same location for forever. Unfortunately, this does not work out for everybody. While the placement for your operation may need to shift, it's impossible to relocate a concrete water tank. Stainless tanks, however, can be moved and set up anywhere. This eliminates the expense of purchasing a new one as well as the hassle of moving it yourself. When your requirements evolve, so can your stainless Steel Water Tank.

Stainless Steel Tanks are more attractive, Concrete tank certainly aren’t that nice to look at; they look dull and are often soiled with mould or graffiti. Stainless tank look more streamlined and professional; they can even be painted to make them a better match for the surrounding environment. It may never be confused for an artistic masterpiece, but when you compare the aesthetic appeal of concrete vs stainless tank, the answer is clear – Its always Stainless Steel Panel Tank by Beltecno.

Concrete tanks are vulnerable to mold, bacterial contamination, and leaks. While getting a concrete tank get cleaned on time can help prevent these problems, but it's not a perfect solution. Stainless steel tanks are impervious to mold, bacterial contamination and leaks. Since they're also non-porous, you shouldn't ever have to worry about the quality of your drinking supply.

They can be re-used if you run a sustainable company or just wish to create a good environmental choice with your water supply, stainless steel tanks win again, too. Stainless steel can be re-cycled, which means that when your company no longer needs to utilize your water tank, these supplies may be used to produce other items. With concrete, there’s really nothing you can do with those resources. Utilizing stainless steel allows you to reap the benefits of a more dependable item while creating an ecologically friendly decision.

.png?width=624&height=325&name=Copy%20of%20FoS%20Header%20Images%20(10).png)

Concrete water tanks vs. Stainless steel water tanks : It's clear that stainless comes out on top when it comes to the benefits. When you need a customized water tank for safe, flexible, and sustainable storage, Beltecno is ready to help. Contact us today!

![]()

For more information regarding our stainless steel panel tanks download our product brochure by clicking the button below, drop us your requirement on sales@beltecnoindia.com or call us on any of given numbers +91 9116009580/+91 7300084028

For more Details on Our Product click here ![]()

*https://pubs.spe.org/en/ogf/ogf-article-detail/?art=3566