Industrial Thermal storage tank precisely made for

Data Centre

Outline

In buffer tanks used for emergency cooling water supply in data centers and similar facilities, it is crucial to maximize the duration of cooling water supply under specified conditions such as predetermined tank capacity and inflow rate.

By approaching a fully plug flow within the tank the cooling water supply duration can be extended. To achieve this, various internal piping provisions are used.

By utilizing simulations with our temperature analysis software, we can design and provide the optimal distributor shape tailored to our customers' requirements.

Roles of buffer tanks

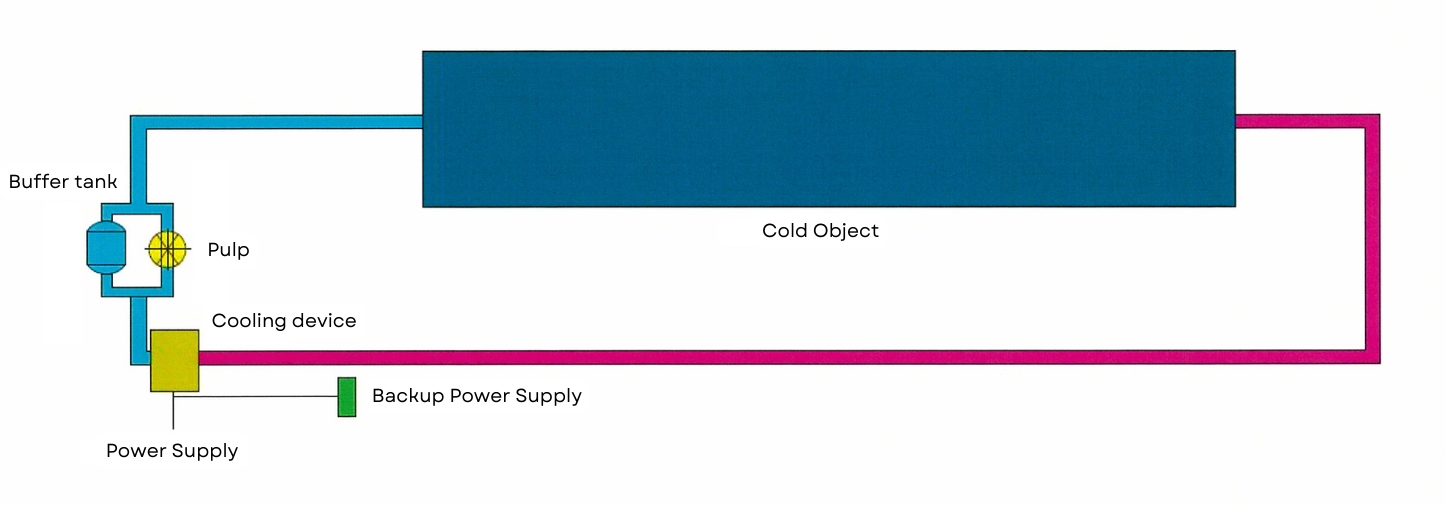

In the system circuit shown above, the cooling device circulates chilled water while cooling the servers. At the same time, the cold water in the buffer tank also passes through, ensuring that cold water is always maintained.

In the event of an emergency and power failure, the system will switch to the backup power supply. However, due to the system's design, this switch takes about 10 minutes. During the time before the cooling system is restored, the buffer tank is used to continue cooling the equipment and maintain normal operation.

Performance of the buffer tanks

Considering the role of the buffer tank, for the same tank size and flow rate, the longer the duration of cold water supply at the outlet, the better the performance of the buffer tank.

The distributor installed on the inlet side is what influences the duration of cold water supply. Generally speaking:

- If a perfect push-flow is formed within the tank, the cold water supply duration will be the longest.

- If short-circuit flow is formed within the tank, the cold water supply duration will be shorter.

-1.png?width=224&height=300&name=image%20(1)-1.png)

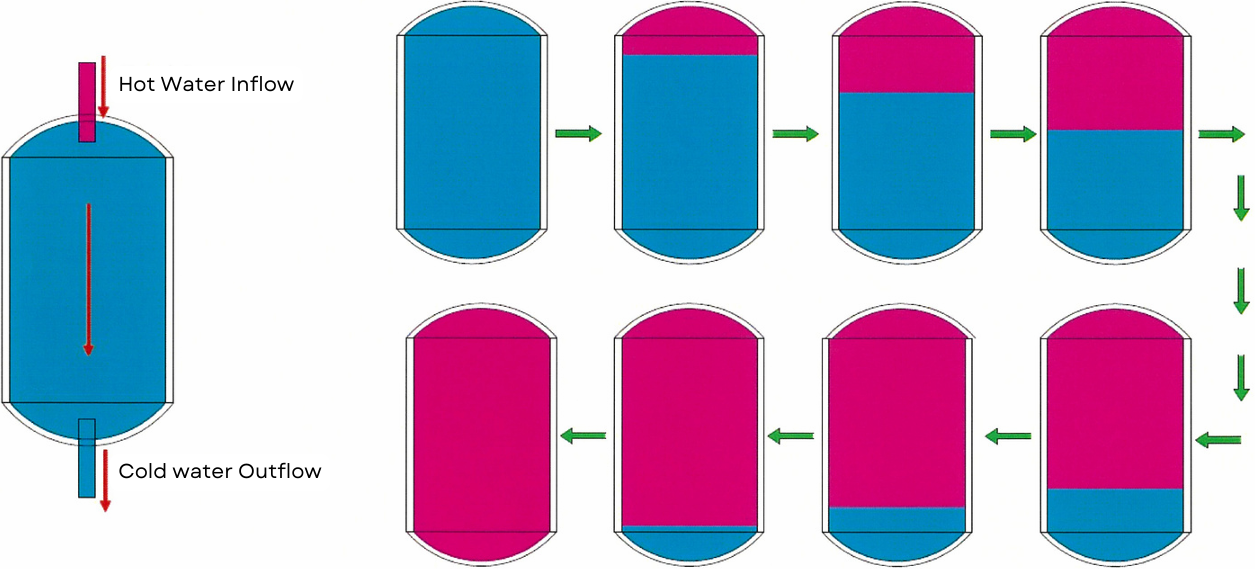

What is a perfect push-flow

As shown in the diagram, the high-temperature water that flows in spreads across the entire cross-section near the inlet side and moves toward the outlet side without mixing with the cold water. This flow condition is called a perfect push-flow, which results in a longer duration of cold water supply. The role of the distributor is to bring the flow closer to this ideal condition within the tank.

To create a push-flow

.png)

As can be understood by imagining the formation of the push-flow in the diagram on the right, the key to forming a push-flow is how to convert the small-diameter high-speed flow into a large-diameter low-speed flow. The distributor is responsible for this conversion, and Beltecno's distributors are designed based on this concept. The specific design of the distributor will be explained next.

The concept of distributor design

Multiple circular plates with different diameters are arranged at regular intervals. The diameter of the central hole in each circular plate is progressively reduced. The inflowing water that passes through each stage enters the tank while its direction is controlled at the outlet. The hole diameters are set so that the flow velocity is nearly the same at each stage outlet.

.png)

.png)

The inflowing water passing through each stage of the circular plates has a faster speed at the center, decelerates radially, and forms an even low-speed flow at the edges of the plates.

As a result, the conversion from the small-area high-speed flow in the pipes to the large-area uniform low-speed flow at the outlets of each stage is achieved.

-1.png)

Temperature analysis (simulation) software

At Beltecno, by using temperature analysis software for simulations, we can analyze the flow conditions inside the buffer tank and design and propose the distributor that best suits the customer's usage conditions. Additionally, the effects of the distributor can be visually confirmed, making it easy to understand the type of water flow formed inside the tank, how long cold water can be supplied, and other related details.

The following conditions are required for the actual simulation:

- Tank capacity (dimensions)

- Flow rate

- Temperature conditions

- Pipe positioning

The above simulation is possible. Since we can also design and manufacture the tank itself, please feel free to contact us if you have any questions.

What is a perfect push-flow

.png)

To create a push-flow

.png)

Tank Usage

We offer large, multi-purpose water storage for industrial and commercial applications.

Huge tanks cater to industries such as manufacturing and pharmaceuticals etc. ensuring substantial storage capacity for critical processes.

Large-scale tanks designed for commercial businesses, including hospitals, hotels, and more. Discover the perfect commercial tank for your needs.

CE Comfort Engineers Pvt. Ltd. specializes in project design, management, material procurement, and execution for factory and industrial expansions. They rely on Beltecno's Stainless Steel Panel Tanks for RO water storage in various applications.

To start, learn more about our products.

Downloading is free.

In our brochure, you will find the following information.

- Why Beltecno's Storage Tanks?

- Detailed specification of Storage Tanks.

- Application of Storage Tanks.

- Types of Storage Tanks (Horizontal & Vertical)